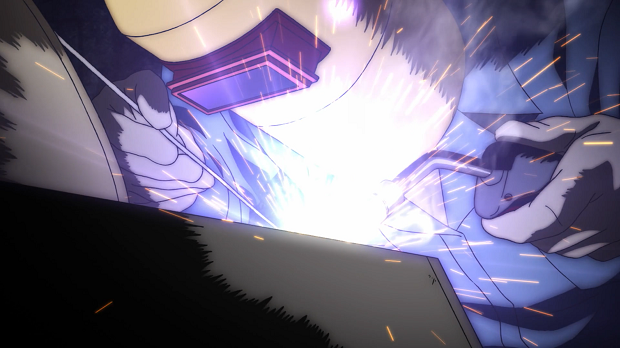

What Are the Most Common Welding Processes?

Sticking two pieces of metal together is one of the most rewarding jobs in the today’s world that requires a fair amount of skills and the right tools for the job as well. Unfortunately, in the welding business there is no single process suitable for all the different applications. There are no “one size fits all” welding machines. Different metals require a different welding process. There is a number of different types of welders available today and each of them has its own unique set of benefits and limitations and requires a different degree of welding skill to operate.

If you plan on getting into the welding business, it is crucial to understand your needs and match them with a specific welding process in order to choose the right welder model option.

Some of the most common welding processes include Stick, MIG, and TIG so, lets go over the basic principles of each process and some of the various applications as well.

For many years stick welding has been one of the most popular method for home-shop welding applications. It uses an electric current that flows from a gap between the metal and the welding stick, which is also known as an arc-welding elWhat Are the Most Common Welding Processesectrode. This type of welding is very effective for welding most alloys or joints and it can be used both outdoors, indoors, and in drafty environments. It is also one of the most cost-effective methods and it is popular due to the ability of creating effective bounds on dirty and even rusty metals. However, stick welding has its own limits. It requires frequent rod changing, it emits significant spatter, and welds must be cleaned after completion. It is also quite difficult to learn and use, especially in mastering the ability to start and maintain an arc. This type of welders are available in AC, DC or AC/DC, with AC being the most economical. Stick welding is still a popular choice for welding thicker metals among farmers, hobbyists and for home maintenance chores.

Next on the list is my personal favourite – the MIG welder. Most Mig welding machines for sale today use a wire welding electrode that is fed automatically at a consistent speed which is pre-selected. The arc which is created by an electrical current between the base metal and the wire, melts the joints and the wire together creating extremely strong welds with great appearance and very little need for cleaning. In fact, MIG welding is one of the cleanest processes, it is easy and can be used on both thin and thicker plate metals. Flux-Cored arc welding is a slight variation on MIG welding and it is most suitable for outdoor conditions and dirty materials. Due to the portable design and high welding speeds it is widely used in construction. Both these types of welders are relatively easy to learn and create very clean welds on various materials, such as steel, stainless steel, and aluminum and they can both weld materials as thin as 26-gauge. Today you can find a wide range of high-quality Mig welding machines for sale at reasonable prices.

Finally, TIG welding is an arc welding process that uses an non-consumable tungsten electrode to create welds. With TIG welding the weld area is protected from contamination by a gas (usually argon) that acts as a shield and a filler metal, though certain welds don’t require this type of protection. TIG welding is mostly used to weld thin section of alloy steel, stainless steel, and non-ferrous metals such as copper alloys, aluminum, and magnesium. Most users choose this type of welding due to the greater control over the weld and the high-quality of the weld itself. However, TIG much more complex and has a steeper learning curve than other welding type and it is also significantly slower.