Digitron Electronics: All You Need to Know About Food Thermometers, Pressure Meters and Gas Leak Detectors

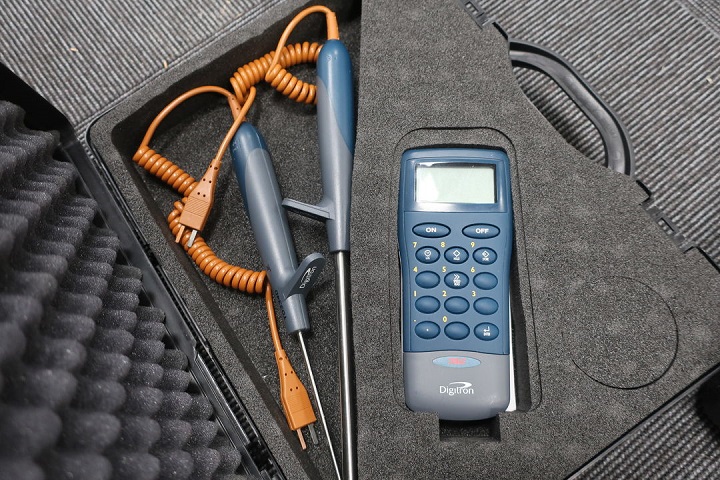

For more than 40 years, Digitron has been designing and manufacturing instrumentation and monitoring solutions and has been a leading supplier for Food, Beverage and HVAC industries all around the world. Their range of Digitron electronic products includes simple and easy-to-use handheld thermometers, pressure meters and dataloggers through their state-of-the-art wireless temperature monitoring solution, which can help you meet safety requirements and manage your HACCP programme.

Food Thermometers: Why You Need One?

Food thermometers are crucial for maintaining your HACCP plan and making sure food is prepared, stored and transported at safe temperatures. A food thermometer is ideal for checking core temperatures of food before serving and can be very useful for catering purposes.

One of the main requirements of being an excellent cook is to have the best cooking tools at all times. We all know that temperature ranges play a key role in how well a meal is prepared. There is no safer and more effective way of making sure that food has been properly prepared than using a thermometer.

A proper food thermometer is one of the essential pieces of equipment that you need in your kitchen. You can find Digitron electronics thermometers that are highly accurate and easily portable. This way you can always ensure the food you prepare has met both the desired temperature and the safest temperature for consumption, especially in restaurants. Restaurants are legally required to comply with the food regulations set by HACCP (Hazard Analysis Critical Control Point).

Pressure Meters: Where Could You Use One?

Carrying out accurate pressure difference measurements during installations and services of domestic and commercial heating systems is very important and plumbers and gas engineers know that. Pressure measuring devices are used to determine absolute pressure, negative and excess, relative pressure for gases, air and/or liquids. There are different varieties of pressure measuring devices on the market, and the following are some of the most important types.

Manometers

A manometer is a type of pressure gauge which uses a column of liquid to measure pressure. It can measure only low pressure, close to the atmospheric pressure or vacuum. The two main categories are simple manometer and differential manometer.

Mechanical Pressure Gauges

They are used for measuring high-pressure ranges. The rack and pinion arrangement magnifies the deformation caused by the application of pressure on the elastic element and the value is displayed on the pointer scale for pressure measurement.

Liquid Filled vs. Dry Pressure Gauges

Liquid-filled pressure gauges are used in circuits having fast and frequent loads, pressure peaks and mechanical vibrations. Dry pressure gauges, on the other hand, are commonly used for industrial applications and prevent corrosion to a greater extent.

Digital Pressure Gauges

Digital pressure gauges are commonly used in temporary industry applications and are preferred over analogue pressure gauges as they are more accurate and stable. The gauge reading is not affected by vibration and a digital gauge won’t need calibration as often. One of the greatest advantages of using a digital pressure meter is that it features multiple units of meters. The corresponding reading is displayed in a simple format that can be easily interpreted.

Digital pressure gauges are primarily used for monitoring and troubleshooting the system. If a pump is left unmonitored, it may easily become a high-maintenance piece of equipment. For that reason, a good set of digital pressure gauges is a well-worth investment and can prevent costly maintenance as the technicians can effectively identify the reason for any pressure drop and repair it immediately.

Wireless Pressure Gauges

These are the latest edition of pressure gauges that can transfer the pressure reading directly to other devices. They provide stable and accurate pressure readings and data can be collected remotely.

Gas Leak Detectors: When to Get One?

To make sure the work undertaken on domestic and commercial systems is leak-free, gas and heating engineers use gas leak detectors. In case a leak is detected, it has to be pinpointed and fixed as soon as possible. The impacts of a commercial or industrial gas leak can be devastating and dangerous to the public and the environment, so it’s most important to prevent one by using a Digitron gas leak detector.

Gas leak detectors can be used to detect toxic, flammable, or combustible gases before they have caused any damage or put anyone at risk. They sense gases that humans can’t smell or see and are an integral line of defence for any business and people’s lives as well. One of their greatest advantages is that they give you time to assess and evaluate a situation in which minutes can mean the difference between an inconvenience and tragedy.

These days, commercial and industrial industries are under more pressure than ever to comply with safety rules and regulations and gas leak detectors can help you meet those standards. They are required by best industry practices and neglecting them may cause a safety breach and violate integral protocols as well. Having gas leak detectors helps you fulfill the standards and ensure safety at the workplace.

Safety always comes first, so you need to make sure the gas leak detectors you choose are some of the safest and most efficient ones available. They are some of the most essential pieces of safety equipment for many businesses and ensuring they’re dependable is a top priority.