The Most Essential Woodworking Supplies for Beginners

Woodworking allows people to create long-lasting, useful items, relieving stress and expressing creativity along the way. It means different things to different people. Whether you’re a hobbyist or professional, you’ll get instant gratification the moment you create your first piece. Of course, doing so requires having the right tools. Professionals already have most of the tools I’ll talk about, but the first-timer might have a hard time choosing from all the different tools available in their local or online woodworking supply store.

It’s easy spending thousands of dollars on tools that you may not even use, at least not in the beginning. At first, you can get away with buying just a few basic tools and build your range up. Not every tool in a woodworking supply store is expensive, and even fewer are complicated in nature. All tools are broken down into five categories, used to cut, finish, assemble, hold and measure all the different wooden parts that will comprise your final product.

Saws for Cutting

Almost every project will start with cutting wood into the right shape and size. Whether it’s hardwood or softwood, you need to cut it into shape using a saw. Saws are available in a wide range of shapes and sizes, and can be used for various cutting tasks. The most popular types of woodworking saws include jigsaws, table saws, hand saws and circular saws. Let’s summarise the difference between them and what their specialties are.

- Jigsaw – Also known as sabre saws due to their reciprocating, sabre-like blades. They’re electrically powered and designed to make straight, curved or serpentine cuts. They perform their cuts with back and forth or up and down motion. Best suited for interior cuts.

- Circular Saw – Called circular for its round blade made up of sharp teeth. All models are electric, and are available in a range of power ratings. Mostly used to perform straight, clean lines. Can be used with ripping blades, crosscut blades and combination blades. The teeth are evenly spaced, and are available in two basic designs – a 90-degree mounted motor and arbour mounted motor.

- Table Saw – Table saws are ideal for achieving cuts that other saws can’t. They’re easily adjustable, allowing for maximum precision. There are three types of table saws, based on the size of the work and where the work is to be performed – cabinet table saws, benchtop and contractor table saws.

- Handsaws – Handsaws are the most simple and easy-to-use saws. They’re ideal for performing detailed, precision cuts. They’re lightweight and affordable. Based on the design, they can be ripping, crosscut, backsaws, combination, coping, carcase and dovetail handsaws.

Filing, Planning and Sanding

Once cut into shape, you’ll need to detail them so they appear attractive. This is done with the help of filing, planning and sanding tools.

- Planes are more cutting tools than sanding devices. They use a fixed blade to remove wood fibres, making them smoother. There are various types of planes – jack planes, block planes, joining planets, rabbet planes, scraper planes and spokeshaves.

- Sanders are fast-action machines that use an abrasive sandpaper disc to remove material, making the wood silky smooth.

- Hand files are used to shape and smoothen wood. They’re affordable and long-lasting. There are three types of hand files – rasps, half-round and mill files.

Assembly Tools

There are many assembly tools, but for beginners, you’ll need the following:

- Hammer – There’s no universal type of hammer for woodworking. You’ll find many different types used for a variety of purposes. Things to consider are the head design (face size and weight), claw design (length and curve), handle composition and overall weight. All hammers are categorised as finishing, framing or tack hammers.

- Mallet – Similar to hammers, but instead feature large or leather heads. Mallets are softer and absorb shock better than hammers.

- Power Drill – Power drills come in many different designs, but for beginners working out in their garage get a corded model, as they’re more affordable and more powerful than their cordless counterparts. Consider the chuck size – 3/8-inch and 1/2-inch chuck sizes are the most common ones.

- Screw Guns – These are the best fasteners for woodworking. They hold well and can easily be removed to disassemble the item you’re assembling. Instead of using screwdrivers, screw guns make driving screws faster and more accurate.

Measuring and Angling Tools

There’s a saying that everyone uses – measure twice cut once. Easy-to-read and quality measuring tools make this reality. Here are some of the most popular:

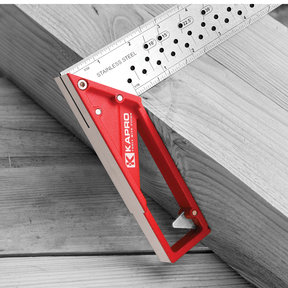

- Squares – Squares are essential for making quality products. You get to create and confirm all types of angles. Some of the squares you should have are framing, try, combination, speed, mitre and bevel squares.

- Tape Measure – At least one of the following types of tape measure are essential – retractable steel, flexible reel, folding rules or yardstick and straight edge rules.

![AFX Sauber F1 C44 Stake No24 Slot Car [22092]](https://www.availableonline.com.au/wp-content/uploads/2025/06/6ccd9e30-c6fa-4910-9081-5fcc3ba80b04__60843-520x245.jpg)