Small But Mighty: An Introduction to Bilge Pumps

Almost every boat ends up with some unwanted water in the bilge, which has to be removed for multiple safety reasons. Whether it gets in from a leaky portlight, a melting ice from the icebox, a propeller shaft packing gland, or leaky seams in a wood boat, it has to be removed one way or another, because if you leave it aboard, it can destabilise your boat, or lift spilled fuel and distribute it throughout the bilge where it can do a lot of damage, or simply sink the boat completely. In order to prevent all of this, an affordable and efficient solution is the bilge pump.

If the leak comes from a hole in the hull, which was made from an impact, it can be quite catastrophic without a bilge pump. Large amounts of water need to be removed with a device with huge pumping capacity. Most of the time, these pumps will buy you enough time to do some emergency repairs to the leak, and enough time to abandon the ship, or limp back to the shore.

Having multiple-pumps can also be helpful, but you shouldn’t just ignore the leak and go on about your trip thinking the pump will keep you afloat. There isn’t a single bilge pump system that is capable of keeping up with leaks caused by hull damage, regardless of the size of the boat.

Pumps are rated by their capacity, which is typically measured in gallons per hour or minute. However, worth knowing is that those measurements are made under open flow conditions without any restrictions to the discharge. Generally, you want to get the largest pump that can fit, and is practical for your boat. The selection can be limited by power limitations and size constraints, but as a general rule of thumb, aim for a 1.000 gallons per hour model, or more, if possible.

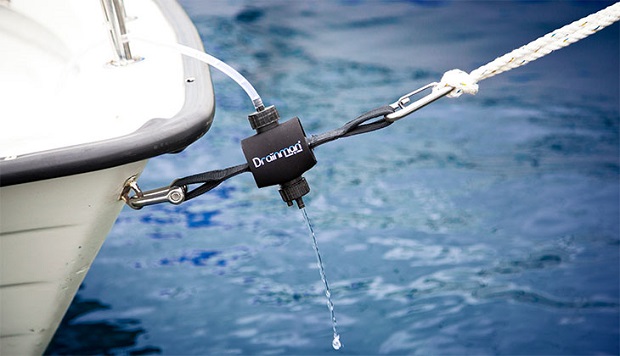

When installing a bilge pump, keep the discharge hoses as short as possible, as longer hoses can reduce their performance because of the higher resistance. Moreover, use smooth bore hoses, even though they’re the more expensive type. The ribbed bore from corrugated hoses reduces pump performance and flow capacity.

Furthermore, always use a vented loop, especially when installing on sailboats where the heel might immerse the fitting which is significantly higher above the waterline when the sailboat floats on even keel. Waterproof butt connectors should also be used for all wiring in the bilge area, as the wires can get water inside the insulation and turn into green mush.

![AFX Sauber F1 C44 Stake No24 Slot Car [22092]](https://www.availableonline.com.au/wp-content/uploads/2025/06/6ccd9e30-c6fa-4910-9081-5fcc3ba80b04__60843-520x245.jpg)