Exploring the Different Types of Milling Machines Available Online

In a realm where metal meets technology, the right milling machine can mean the difference between a standard job and a masterpiece of craftsmanship. As the backbone of countless industries, professionals use these instruments to create anything from car parts to even aircraft structures. They come in a dizzying array of types and configurations, and each has a specific set of tasks and applications.

Now, you can find different types of milling machines, depending on your needs and budget. Vertical machines are fantastic for tasks like drilling, slot cutting, and face milling. The heavy-duty ones are perfect for cutting grooves, shoulders, and slots in heavy materials. If versatility is what you’re after, the universal machines have a swivelling worktable and you can adjust them to various angles, making them adaptable for a wide range of operations.

Whether you’re a seasoned machinist or a newcomer intrigued by the possibilities of these machines, let’s uncover the different types that power precision in our modern world!

Vertical

These tall, sturdy pillars have a vertically oriented spindle, which means that the cutter moves up and down as it interacts with the workpiece. You can use them to create precise holes in your workpiece with ease. This is especially handy when you need holes of different sizes or depths in various parts of your project.

Slot cutting is another bread-and-butter operation for vertical milling machines in Australia. Whether you’re making keyways, grooves, or T-slots, the vertical setup provides stability and accuracy for these tasks. When you’re working on a project that requires perfectly flat and smooth surfaces, these instruments shine. They’re excellent for face milling, where the cutter removes material from the face of your workpiece, resulting in a smooth finish.

Imagine you need to create pockets or recesses in your workpiece. Vertical machines are your go-to tool for this. With their precise control over the cutter’s depth, you can easily mill out pockets of various sizes and shapes to fit specific components or features.

Horizontal

One of the standout features of horizontal milling machines is their strength and stability. When you’re working with large, solid pieces of metal or other materials, you want a device that can handle the job without breaking a sweat. Horizontal mills are your go-to for tasks that require intricate and complex machining. Whether you’re crafting gears, splines, or threads, the horizontal setup allows for precise indexing and rotation, resulting in extremely accurate and finely detailed work.

Here’s where horizontal mills truly stand out: when you need to cut multiple surfaces of a workpiece simultaneously. These machines employ multiple cutters and perform various operations at the same time, which can reduce your working time. Additionally, workers often use horizontal mills for tasks like machining large, flat metal plates or producing custom moulds for casting processes. Their rigidity and precision make them indispensable in industries like aerospace, automotive, and manufacturing.

Universal

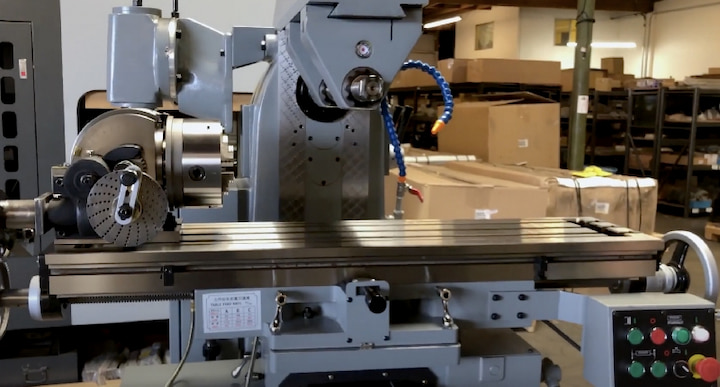

But what if you had a single device that could adapt to various tasks, like a Swiss Army knife of the machining world? That’s where the versatile universal milling machine comes in. What sets these devices apart is their swivelling worktable. This pivotal feature allows you to adjust the angle of the workpiece, which makes it a powerhouse for tasks that require milling at different angles and orientations. Think of it as your go-to instrument when you need flexibility in your project.

One of the primary applications of this type of machine is general-purpose milling. Whether you’re drilling, slotting, or facing, these devices can handle a wide array of tasks with precision. They’re fantastic for working on complex projects that involve multiple angles. If you’re into gear manufacturing or require precision cutting of gears, this device is a reliable choice. The swivelling table allows for the precise indexing that you need to cut gears with different tooth profiles and angles.

Turret

Unlike some other milling machines online that have a fixed spindle, turret mills have a rotating turret head that can hold multiple cutting tools. This turret head can swivel a full 360 degrees. With other types, if you want to change the cutting tool, you often need to stop the machine, manually replace the tool, and then recalibrate everything. But with a turret mill, you have an array of cutting tools preloaded in the turret head. When you need to change the tool for a specific task, you simply rotate the head towards the tool you want to use.

This feature makes turret mills ideal for jobs that require multiple tool changes or different cutting operations. Whether you’re drilling precise holes, making keyways, creating slots, or machining complex parts with various angles, a turret mill can handle it with ease.

CNC

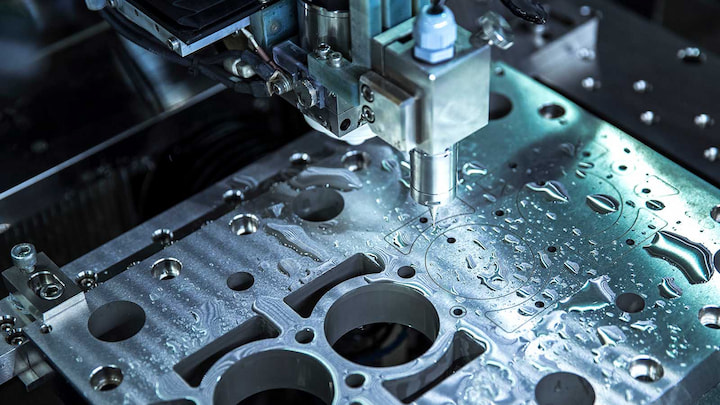

CNC stands for Computer Numerical Control, which means that these machines are like skilled artists. You feed them a digital blueprint of your design, and it follows those instructions to a tee. They can create parts with tolerances measured in thousandths of an inch. This makes them perfect for industries where accuracy is non-negotiable, like aerospace and medical device manufacturing.

Customisation is another strong suit. Whether you’re prototyping a new product or crafting a one-of-a-kind piece, CNC machines are your creative accomplice. Want a part with unique features or a personalised design? Just programme it, and the device brings your vision to life.

What’s the Difference Between CNC Milling and Manual Milling?

A manual milling machine is fantastic for certain tasks. It’s great for simple jobs, especially when you’re working on one-offs or small batches of parts. Think of it as a bit like woodworking—you have control over every cut, and it’s almost an art form. On the other hand, with CNC milling, you’re dealing with a computer programme. You input a digital design into a computer, and that programme controls the entire process.

Automation makes a big difference here. In CNC milling, the machine itself moves the cutting tool precisely according to the program’s instructions. It’s like having a robotic craftsman at your disposal. This means tight tolerances and consistent quality because there’s less room for human error. So, if you have a part with intricate geometries or complex 3D shapes, a CNC machine can handle it effortlessly. It can move in multiple axes simultaneously, creating designs that would be nearly impossible to do manually.

![AFX Sauber F1 C44 Stake No24 Slot Car [22092]](https://www.availableonline.com.au/wp-content/uploads/2025/06/6ccd9e30-c6fa-4910-9081-5fcc3ba80b04__60843-520x245.jpg)